We have a dedicated maintenance team that helps us keep our machines in good condition with regular preventive maintenance, and thus help service our clients well. In terms of machine infrastructure, we have the below-mentioned machines. They help us build the expected volume, and also the capability to make accurate, precise cartons.

HOW WE SERVE YOU

INFRASTRUCTURE

Shop Floor

We at CorruCase believe in keeping up with the latest trends and always keep on upgrading ourselves with the latest available technologies.

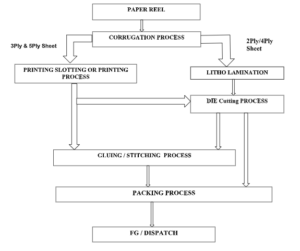

Manufacturing Process

Our manufacturing process has been perfected over years

QA Labs

All the equipment is calibrated regularly on a quarterly basis through an annual contract.

Logistics

Customers get GPS location tracking to deliver our material on time, the option of JIT, and a dedicated, finished product warehouse.

SHOP FLOOR

Our Machines

Automatic 5ply Corrugator from Wanlian, China

Automatic 5ply Corrugator from Wanlian, China

The corrugator is equipped with german web guiding and tensions control attachments, helping us deliver proper finished corrugated boards and boxes with excellent precision.

Automatic flat bed die-cutter machine

Automatic flat bed die-cutter machine

We have an automatic flatbed die-cutter from Bobst’s group company from China Shanghai Eterna.

Printer Slotter With in-line Rotary diecutter

Flexo Printer Slotter with Inline Rotary Die-Cutter

We have a Flexo printer slotter with inline rotary die-cutter for various precisely cut boxes.

Automatic Glue Kitchen Machine

Automatic Glue Kitchen

The automatic glue kitchen machine helps us to make in-house glue with excellent precision, consistent viscosity. The gel point helps us deliver accurate boards with the proper bond strength and high compression.

The machine can store the recipe in its plc controlled through an HMI. Thus, making it very simple for the operator at the click of a button and helps avoid wastages and inconsistency in glue production.

Automatic Folder Gluer machine

Automatic Folder Gluer Machine

We have an automatic folder gluer machine with inside and outside pasting options with glue dispensing attachment from Valco Melton.

Conveyors System to store WIP material

Conveyors System to store WIP material.

The conveyors help us with the more natural movement of WIP by maintaining FIFO. It also makes the process more automatic with fewer human touch points leading to improved board quality in terms of board caliper(thickness) and thus helping reduce the strength loss due to loss of caliper during the various production process.

Where imperfections are perfected

Our Laboratory

We have a fully equipped laboratory with all the latest equipment. All the equipment is calibrated regularly every quarter through an annual contract.

EQUIPMENTS

B.S & B.F Testing machine

Crush tester

COBB testing machine

GSM testing machine

Computerized Compression Testing

Oven

We Know How to Reach You

Logistics

We Have our Own Transport

We have our own transport.

We have a fleet of 9 full body 32 ft containers with GPS location tracking, helping us deliver our material on time without unnecessary delays during transit. We also provide our customers with the option of JIT and a dedicated, finished products warehouse of 10,000sq ft, and an extension of a further 20,000 sq ft is under construction.

We can service and support our clients with JIT over 1000kms from our location because of this dedicated company owned transport and warehousing facility.